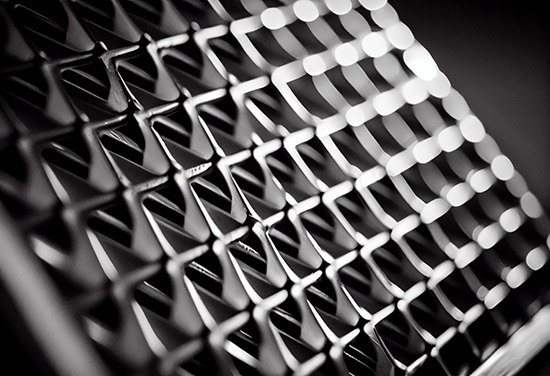

WIRE FOR AGGREGATE SCREENS

ELEVATE YOUR AGGREGATE SCREEN MANUFACTURING

Welcome to the future of aggregate screen manufacturing with Screen Max, a proven engineered steel wire for the construction and infrastructure markets.

Say goodbye to the limitations of oil-tempered wire and embrace a new era of enhanced performance and efficiency.

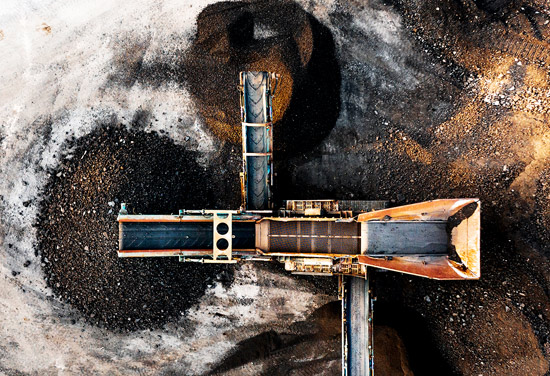

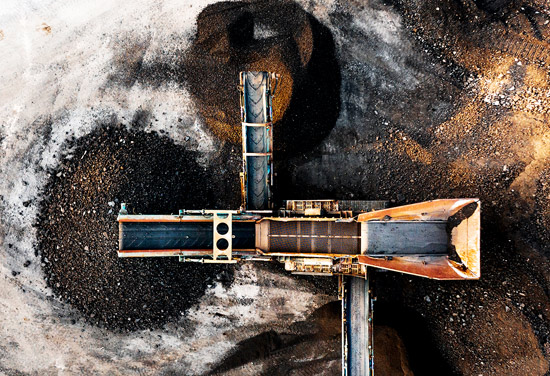

AGGREGATE SCREEN MANUFACTURING

The aggregate screen manufacturing industry specializes in producing essential components for the construction and mining sectors. These screens, typically crafted from high-quality steel wire, play a pivotal role in the efficient sorting and processing of raw materials, ensuring optimal productivity and quality in various industrial applications.

UNMATCHED DURABILITY AND RESISTANCE

Screen Max is not just a wire; it’s a game-changer in the industry. Its superior resistance properties translate to fewer breakages during the crimping process, ensuring a smoother production flow. With Screen Max, you’ll experience a significant reduction in downtime, ultimately leading to substantial cost savings.

Less Breakage, More Reliability

Experience minimal breakage during crimping, resulting in a more efficient and streamlined manufacturing process.

Extended Service Life

Your finished aggregate screen products will last longer, thanks to Screen Max’s exceptional abrasion and breakage resistance. This translates to reduced replacement costs and increased profitability.

UNPARALLELED FLEXIBILITY IN OPERATION

At the heart of Screen Max’s innovation lies its remarkable flexibility during operation. This wire allows for seamless diameter changeovers, optimizing your production process. Lower inventory requirements and reduced storage space mean you can allocate resources more efficiently, ultimately boosting your bottom line.

Effortless Diameter Changeovers

Say goodbye to cumbersome processes. With Screen Max, transitioning between different diameters is a breeze, enhancing operational efficiency.

Optimized Inventory Management

Reduce the required space for inventory, freeing up valuable space and capital for other critical operations.

AMPLIFY PRODUCTIVITY AND SAFETY

Screen Max is engineered to not only endure but to excel. Experience more efficient startups while maintaining the highest standards of safety. Your employees deserve the best, and Screen Max delivers.

Efficient Startups

Get your operations up and running faster, minimizing downtime, and ensuring you meet deadlines consistently.

Enhanced Handling Safety

Prioritize the well-being of your workforce. Screen Max is designed with safety in mind, providing peace of mind for you and your team.

PRODUCT CHARACTERISTICS

GRADES

1050 to 1065, 1541

FINISHES

Bright (drawn soap finish)

DIAMETERS

- 0.047 to 0.075″ (1.2 mm to 1.9 mm):

+/- 0.001″ (0.025 mm) - 0.075 to 0.375″ (1.9 mm to 9.5 mm):

+/- 0.002″ (0.050 mm) - 0.375 to 0.625″ (9.5 mm to 15.9 mm):

+/- 0.003″ (0.075 mm)

PACKAGING

800 to 4000lbs on carriers, depending on wire size and customer requirement

OTHER SPECIFICATIONS

Download our spec sheet.

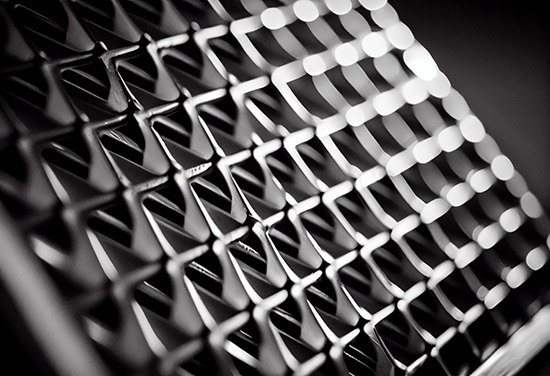

Screen Max IN THE FIELD

In a world driven by innovation

Screen Max stands at the forefront of progress in aggregate screen manufacturing. Elevate your operations, increase profitability, and prioritize safety with the unmatched capabilities of Screen Max wire.