Wire for Garage Door Spring

REVOLUTIONIZE GARAGE DOOR SPRING MANUFACTURING

Elevate your garage door torsion spring production to new heights with Torsion Pro, the pinnacle of steel wire technology tailored for the residential and commercial construction market.

Leave behind the limitations of conventional oil-tempered wire and step into a future of heightened productivity and efficiency.

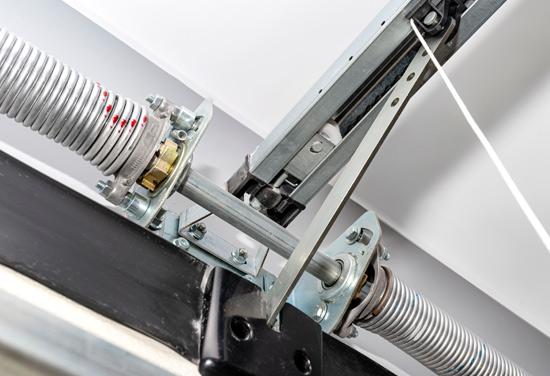

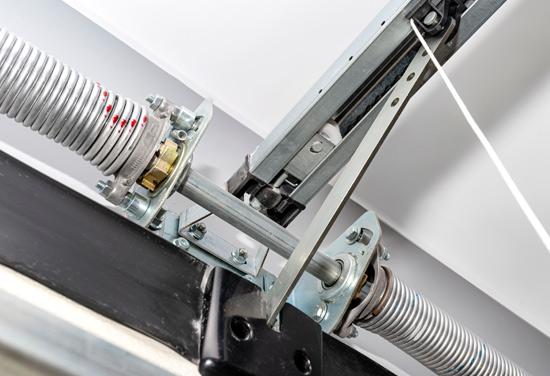

GARAGE DOOR SPRING MANUFACTURING

The garage door spring manufacturing industry is crucial to the functioning of residential and commercial overhead doors. These springs, typically constructed from high-tensile steel, provide the necessary counterbalance to facilitate smooth and controlled movement, ensuring safety and reliability in garage door operations.

UNMATCHED FLEXIBILITY IN OPERATION

Torsion Pro redefines what’s possible in garage door torsion spring manufacturing. Its exceptional flexibility during operation empowers you to seamlessly transition between different diameters, optimizing your production process. Lower inventory requirements and reduced storage space mean you can allocate resources more efficiently, ultimately boosting your bottom line.

Seamless Diameter Changeovers

Effortlessly adapt to changing requirements. With Torsion Pro, transitioning between different diameters is a smooth, hassle-free process.

Optimized Inventory Management

Drastically reduce the allocated space for inventory, liberating valuable area and capital for other crucial operations.

UNRIVALED PRODUCTIVITY AND SAFETY

Experience a quantum leap in productivity and safety with Torsion Pro. By converting your manufacturing equipment and process to accommodate Torsion Pro, you’ll witness longer production runs, more efficient startups, and enhanced operator safety. Your workforce deserves the best, and Torsion Pro delivers.

Extended Run Times

Maximize output with longer, uninterrupted production runs, pushing the boundaries of productivity.

Efficient Startups

Minimize downtime and meet deadlines consistently with swift, efficient startups.

Enhanced Handling Safety

Prioritize the well-being of your team. Torsion Pro is designed with safety at its core, providing peace of mind for you and your operators.

A GREENER TOMORROW WITH TORSION PRO

Embrace a more environmentally conscious approach to manufacturing. Torsion Pro boasts an impressive 30% longer cycle life, reducing the frequency of replacements and minimizing waste. Its clean, scale-free, and oil-free composition ensures a cleaner, more sustainable production process. Say goodbye to the environmental impact of traditional wire.

Extended Cycle Life

Reduce waste and minimize environmental impact with Torsion Pro’s extended cycle life. Reached up to 14,000 cycles in laboratory conditions.

Clean, Scale-Free Composition

Enjoy a cleaner, more sustainable manufacturing process, free from the environmental implications of traditional wire.

Mechanical-Damage-Free Packaging

Ensure your wire arrives in pristine condition, minimizing issues, rejects, and environmental footprint.

PRODUCT CHARACTERISTICS

GRADES

1070 to 1080

FINISHES

Bright (soap drawn finish), Galvanized

DIAMETERS

- Bright: 0.177 to 0.400″ (4.5 mm to 10.2 mm):

+/- 0.001″ (0.025 mm) - Bright: 0.400 to 0.625″ (10.2 mm to 15.9 mm):

+/- 0.002″ (0.050 mm) - Galvanized: 0.177 to 0.380″ (4.5 mm to 9.6 mm):

+/- 0.001″ (0.025 mm)

PACKAGING

2000 – 4000lbs carriers

OTHER SPECIFICATIONS

Download our spec sheet.

Torsion Pro IN THE FIELD

IN A WORLD DRIVEN BY PROGRESS

Torsion Pro stands as a beacon of innovation in garage door torsion spring manufacturing. Elevate your operations, increase productivity, and prioritize sustainability with the unmatched capabilities of Torsion Pro wire.